The project

This project will develop, install a MW scale pilot plant to demonstrate SE-SMR and GTI’s Compact Hydrogen Generator Technology

The pilot-scale demonstration constructed in this project will demonstrate the process as an integrated system for commercial industrial deployment.

The novel hydrogen production process, invented by GTI, is based on the sorption enhanced steam methane reforming (SE-SMR) process and provides the opportunity to deliver bulk quantities of economically and efficiently produced low carbon hydrogen.

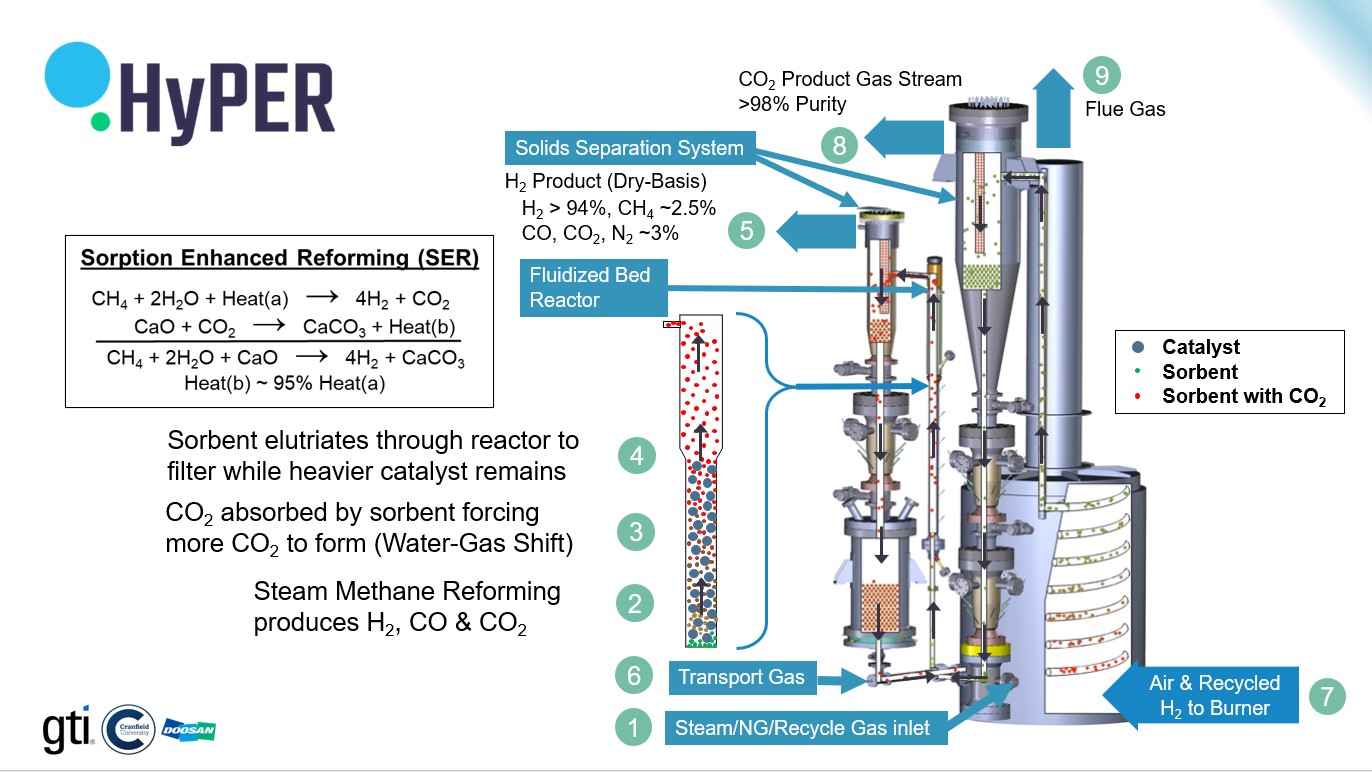

The sorption enhanced steam methane reforming process converts natural gas and steam into hydrogen (H2) and carbon dioxide (CO2) in the presence of a catalyst and a CO2 sorbent. The CO2 is then captured and removed from the gas stream, meaning a nearly pure stream of hydrogen is produced. The sorbent with the captured CO2 is then transported into a separate reactor where the sorbent is heated to remove the CO2, producing another nearly pure stream of CO2 that can be transported and stored or converted into a useful product.

A key element of the HyPER project is to demonstrate the pressurisation of the process, as this will dramatically improve the economics of the process. In existing commercial processes that produce H2, CO2 is emitted throughout the process and the flue gas must be cleaned up at the end by adding a carbon capture plant at the tail end of the plant. In the SE-SMR process, CO2 capture is integral to the operation and actually increases hydrogen production.

Compared to existing commercialised processes with tail end carbon capture and storage, at 24 bara operation, the GTI compact hydrogen generator can achieve:

- ~25% lower Levelised Cost of Hydrogen

- >50% reduction in CAPEX with similar OPEX

- ~97% CO2 capture rates with equivalent H2 purity

- <40% lower carbon footprint (improved efficiency)

- Smaller physical footprint due to process integration

- Potential to scale up to the hundreds of MW